CNC drilling lots and lots of holes!

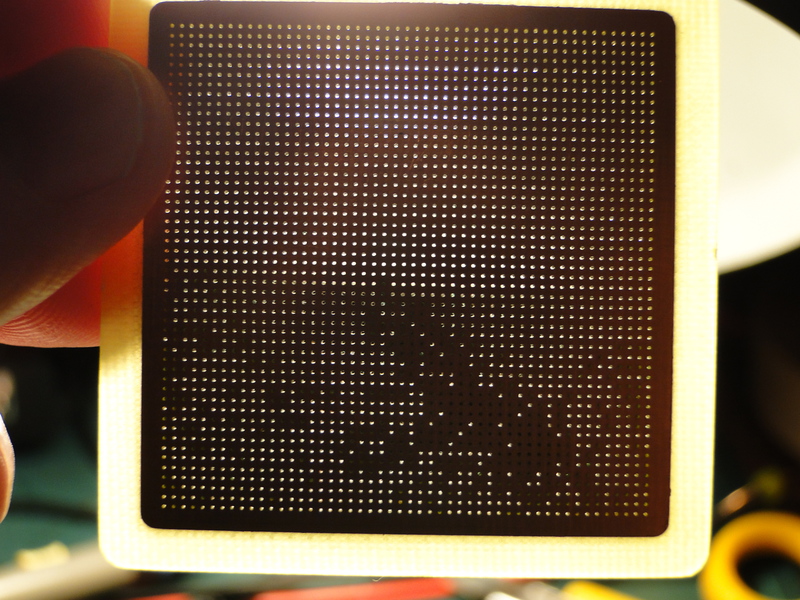

My friend Alan Yates is currently working through all manner or particle detectors. His latest one is a Gas Electron Multiplier. It’s basically a very two very thin plates with many tiny holes that electrons can go through triggering an electron avalanche between the two highly charged plates.

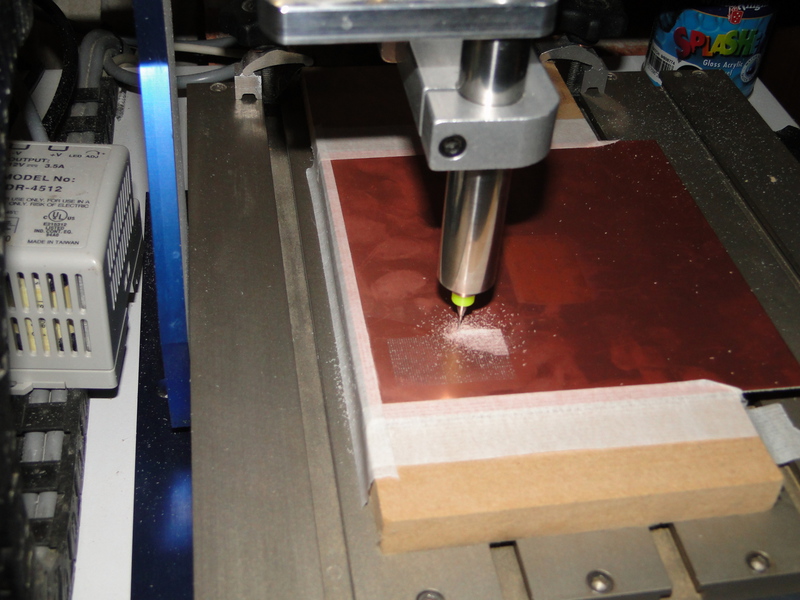

He was going to try using a piece of veroboard, when I said I’d make him something on the CNC.

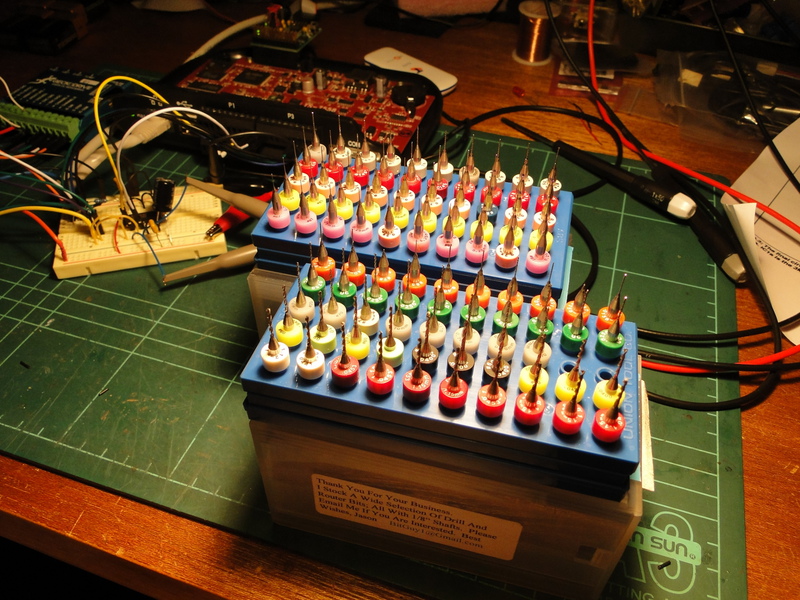

Thanks to Tyson I have a good set of solid carbide PCB drills down to 0.25mm. Alan was only after 0.3mm and 0.5mm spacing so I easily managed that on the Widgitmaster machine.

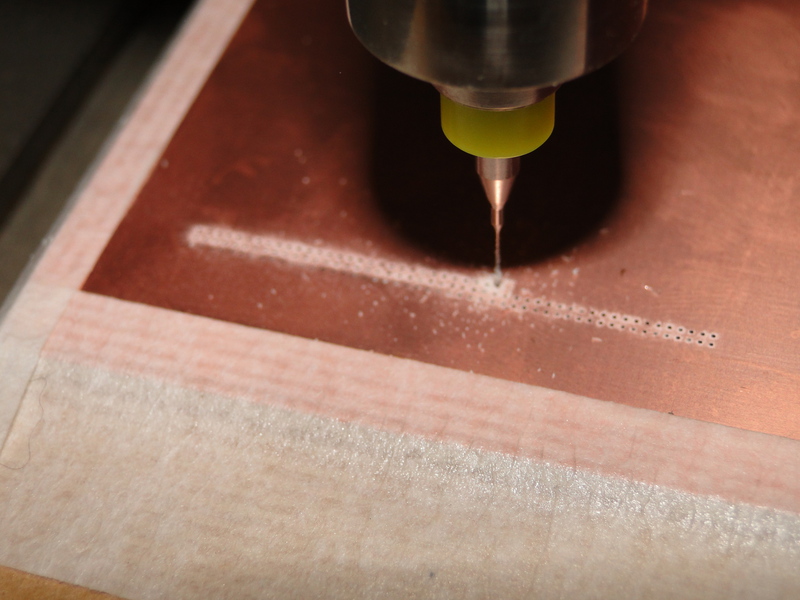

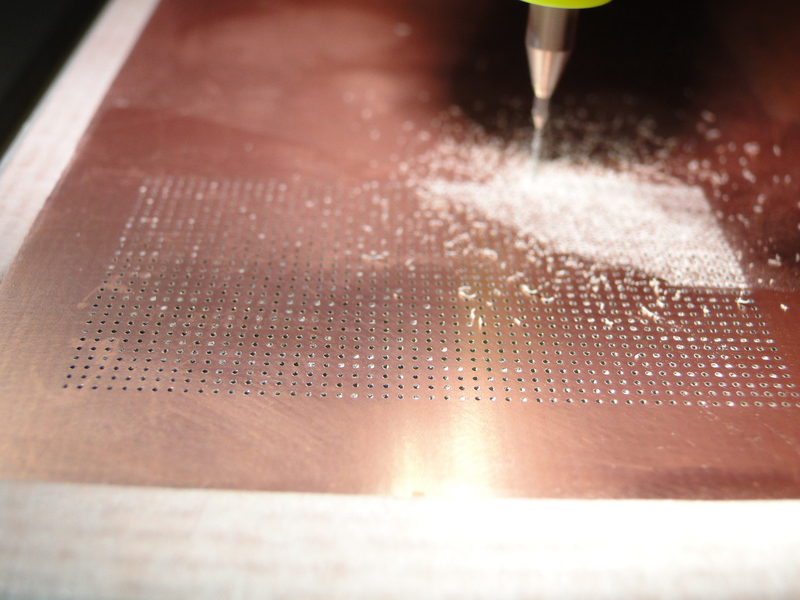

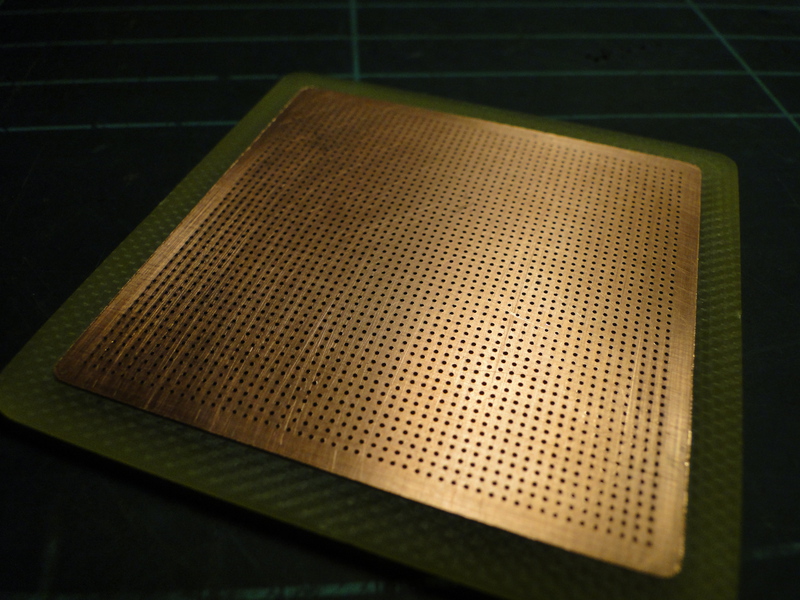

So in the end I ended up with a 70mmx70mm piece of double sided PCB material on the CNC, which drilled 2500 0.306mm holes at 0.5mm spacing.

The results where very impressive and hopefully will work as required. The holes are so small that the dust from the PCB material has clogged a few holes.

I had cleaned up half of them with a small piece of wire, but I left the rest to Alan to deal with as it’s quite laborious! :)

Comments